Applications

Manufacturers & Exporters of Brass

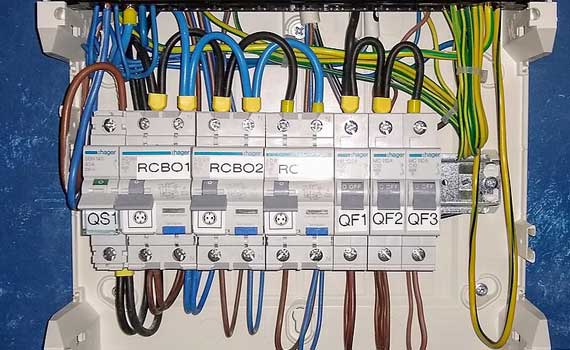

Electrical

Brass components play a crucial role in the electrical industry due to their exceptional conductivity, corrosion resistance, and durability. They are extensively used in electrical connectors, terminals, switches, and sockets, ensuring reliable electrical connections and transmission. Brass's malleability allows for intricate designs and precise manufacturing, meeting the diverse needs of electrical applications. Additionally, its thermal conductivity properties make brass components suitable for managing heat in electrical systems, further enhancing their reliability and performance.

Automotive

Brass components serve numerous critical functions within the automotive industry, leveraging their exceptional strength, corrosion resistance, and thermal conductivity. They are commonly employed in engine components such as valves, manifolds, and bushings, where durability and performance are paramount. Additionally, brass fittings and connectors are used extensively in fuel systems, ensuring reliable fuel delivery and containment. Their malleability allows for intricate designs in electrical connectors and terminals, supporting efficient electrical systems in vehicles. Overall, brass components contribute significantly to the reliability, safety, and performance of automobiles.

Oil & Gas

Brass components play a vital role in the oil and gas industry, offering superior corrosion resistance and reliability in harsh environments. They are extensively used in valves, fittings, and connectors for both upstream and downstream operations, ensuring the integrity of pipelines and equipment. Brass's ability to withstand high temperatures and pressures makes it an ideal choice for various applications, including instrumentation, control systems, and fluid handling equipment. Additionally, brass alloys are often selected for their resistance to sulfide stress cracking, enhancing safety and longevity in oil and gas operations.

Medical

Brass components play a crucial role in the medical industry, offering a balance of biocompatibility, sterilizability, and durability. They are widely utilized in medical instruments and equipment such as surgical tools, dental instruments, and orthopedic implants, where precision and reliability are essential. Brass's antimicrobial properties make it suitable for applications requiring strict hygiene standards, contributing to infection control protocols. Additionally, brass alloys are used in the manufacture of medical gas fittings and connectors, ensuring safe and efficient delivery of gases in healthcare facilities. Overall, brass components support critical functions in medical settings, enhancing patient care and safety.

Hydraulic

Brass components find widespread application in the hydraulic industry due to their excellent corrosion resistance, high tensile strength, and malleability. They are commonly used in hydraulic fittings, valves, couplings, and manifolds, where reliability and durability are paramount. Their ability to withstand high-pressure environments makes them ideal for ensuring fluid control and transmission in hydraulic systems, contributing to the overall efficiency and safety of operations.

Construction

Brass components are integral to the construction industry, offering a combination of strength, corrosion resistance, and aesthetic appeal. They are commonly utilized in architectural hardware such as door handles, hinges, and fittings, providing both functionality and style to buildings. Brass plumbing fixtures, valves, and fittings are also prevalent, ensuring durable and reliable water distribution systems in residential and commercial constructions. Moreover, brass fasteners and decorative elements add a touch of elegance to interior and exterior design, making brass a versatile choice in construction applications.

Manufacturing

Brass components play a vital role in the manufacturing industry, offering a blend of strength, machinability, and corrosion resistance. They are commonly utilized in machinery and equipment such as gears, bearings, and bushings, where precision and reliability are crucial. Brass fittings and connectors are widely used in fluid handling systems, ensuring efficient and leak-free operations. Additionally, brass alloys find applications in tooling and dies, providing durability and wear resistance for manufacturing processes such as stamping and molding. Overall, brass components contribute significantly to the efficiency and reliability of manufacturing operations.